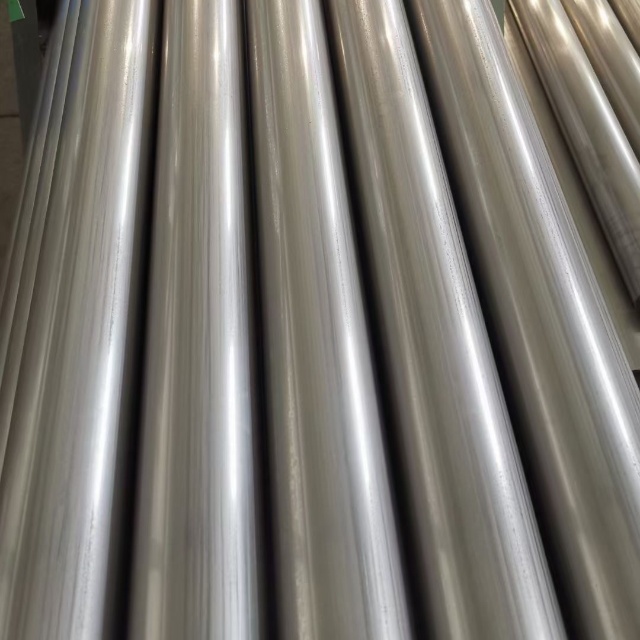

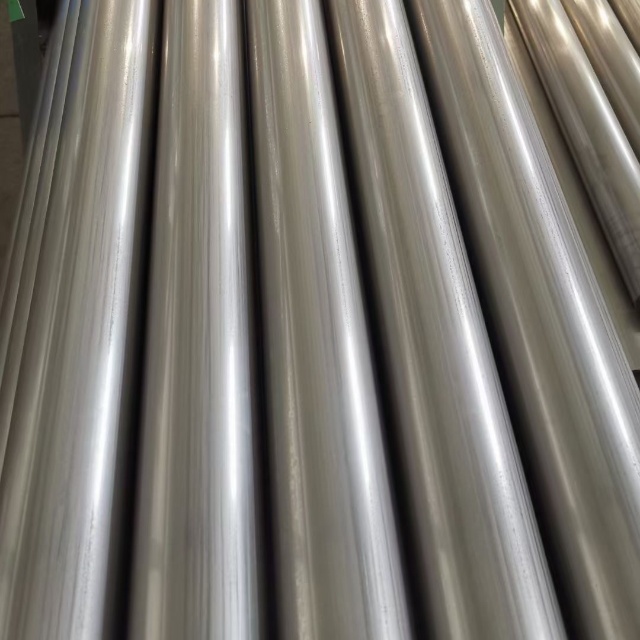

Product Overview

Crafted from 304/316L stainless steel (per ASTM A213), it delivers exceptional corrosion resistance and structural stability—making it suitable for chemical processing, food production, and medical equipment. The seamless manufacturing process eliminates weld defects, ensuring uniform performance across the tube’s length (6m–12m standard lengths), with customizable diameters (12.7mm–159mm) and wall thicknesses (1.0mm–6.0mm) to meet specific industry needs.

Product Features

Corrosion Resistance: 304 stainless steel (18–20% chromium, 8–10.5% nickel) resists mild acids, alkalis, and saltwater (up to 3% NaCl), while 316L (16–18% chromium, 10–14% nickel, 2–3% molybdenum) withstands harsh chemicals (e.g., 5% sulfuric acid, 10% sodium hydroxide) and high chloride environments. Both grades pass 10,000 hours of salt spray testing (ASTM B117) without rust.

Seamless Performance: Seamless construction (per ASTM A213) ensures no weak points, with a smooth inner surface (Ra ≤ 0.8μm) that minimizes fluid flow resistance by 10–15% (critical for chemical and food processing lines). The tube’s burst pressure is 4x the working pressure (up to 30 MPa for 316L, 25mm OD, 3.0mm wall).

Temperature Adaptability: Operates reliably from -200℃ to 600℃ (304 grade) and -196℃ to 800℃ (316L grade). Suitable for cryogenic applications (e.g., liquid nitrogen transfer) and high-temperature processes (e.g., steam lines in food sterilization).

Hygienic Compliance: 316L grade meets FDA 21 CFR Part 177.2600 and EU 10/2011 standards for food contact, with a passivated surface that prevents bacterial growth (total aerobic bacteria < 10 CFU/cm²). Ideal for food, beverage, and pharmaceutical production.

Applications

Chemical Processing: Used in chemical transfer lines, reactor coils, and distillation columns for their corrosion resistance. 316L tubes handle aggressive chemicals (e.g., hydrochloric acid, methanol) without metal ion leaching, ensuring product purity.

Food and Beverage Industry: Ideal for dairy processing (milk, cheese), beverage production (beer, wine), and food sterilization lines. The seamless, hygienic surface is easy to clean (CIP/SIP compatible), meeting 3-A Sanitary Standards.

Medical Equipment: Used in hospital sterilization systems, pharmaceutical manufacturing, and laboratory equipment (e.g., HPLC columns). 316L stainless steel’s biocompatibility prevents adverse reactions with medical fluids and tissues.

FAQ

Q: What is the difference between 304 and 316L grades, and how do I choose?

A: 304 is cost-effective (20–30% cheaper than 316L) for mild environments (e.g., water treatment, indoor piping). 316L is better for harsh conditions (chemicals, saltwater, high temperatures) and food/medical applications. We can provide a material selection guide based on your application details.

Q: Do you offer sanitary polishing for food/medical use, and what is the finish quality?

A: Yes—sanitary polishing is available with a surface finish of Ra ≤ 0.2μm (mirror finish) for food/medical applications. Polishing adds 3–5 working days to the lead time and costs 25–30% above standard pricing. We provide surface roughness test reports for polished tubes.

Q: What certifications are available, and can you provide traceability documentation?

A: Certifications include ASTM A213, ISO 9001, FDA 21 CFR Part 177.2600, and 3-A Sanitary Standards (for polished 316L). Traceability documentation (batch number, heat number, MTR) is provided with every shipment, enabling full supply chain tracking.