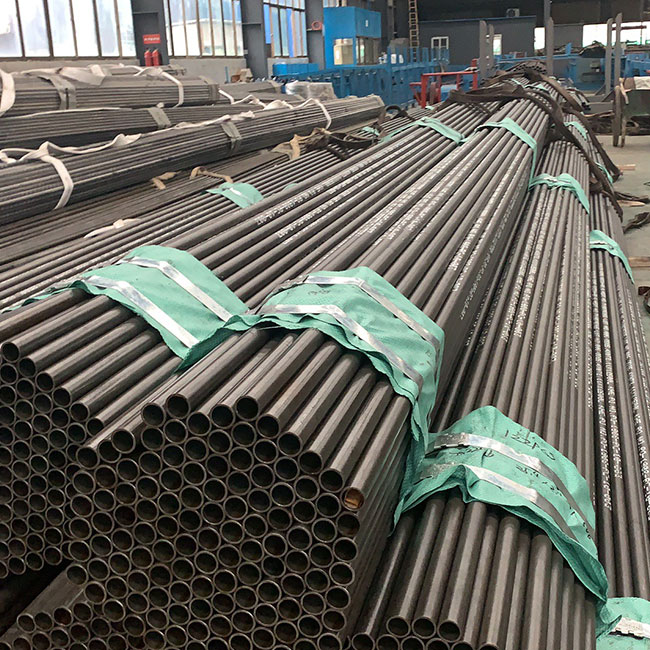

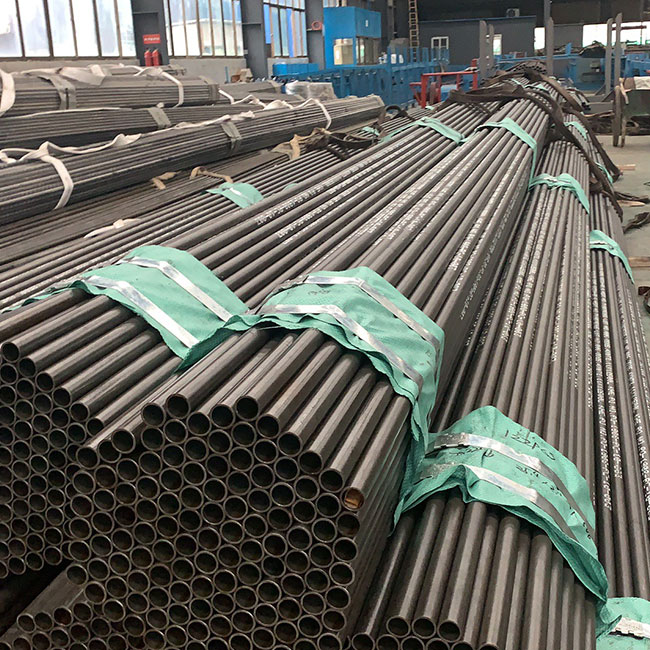

Product Overview

Its wide size range (1-inch OD to 4-inch OD) and robust carbon steel construction make it suitable for structural, fluid, and mechanical uses—with common specifications available in stock for same-day shipping, reducing project downtime.

Product Features

Dimensional Precision: Outer diameter ranges from 1–4 inches (25.4mm–101.6mm) with wall thickness tolerance of ±5%, adhering to industrial fitting requirements (e.g., compatible with ANSI/ASME B16.9 pipe fittings). Each tube undergoes laser diameter measurement along its entire length (sampling every 10cm) to ensure uniformity, avoiding leaks at threaded or welded joints.

Material Versatility: Available in two grades to match diverse load needs: Grade 1010 (tensile strength 365 MPa, ideal for low-temperature applications like refrigeration piping) and Grade 1020 (tensile strength 414 MPa, suitable for medium-temperature loads like compressed air lines). Both grades have good machinability, enabling easy drilling, threading, and bending on-site.

Processing Flexibility: Offered in hot-finished (HF) or cold-drawn (CD) options: HF tubes (wall thickness 2.77mm–12.7mm) are cost-effective for structural uses (e.g., equipment frames), while CD tubes (wall thickness 1.65mm–8.18mm) have a smoother surface (Ra ≤ 1.6μm) for fluid transfer, reducing pressure drop in oil/water pipelines.

Cost-Effectiveness: Carbon steel construction reduces costs by 20–30% compared to stainless steel alternatives (e.g., 304 stainless steel tubes of the same size cost 2.5x more). The tube’s long service life (8–12 years in indoor environments, 5–7 years outdoors with basic rust protection) further lowers total ownership costs.

Applications

Mechanical Engineering: Used for machine frames (providing rigid support for industrial lathes and presses) and hydraulic system piping (transmitting hydraulic oil at pressures up to 7 MPa). Grade 1020 tubes are preferred here for their balance of strength and machinability.

Construction: Structural support in industrial buildings (e.g., pipe racks for factory pipelines) and equipment platforms (e.g., walkways around tanks). Hot-finished tubes are often chosen for this sector due to their lower cost and thicker walls, enhancing load-bearing capacity.

Fluid Transport: Transfers water (potable or industrial), oil (lubricating or fuel), and compressed air in factories. Cold-drawn tubes are ideal for drinking water applications (material meets NSF/ANSI 61) and compressed air lines (smooth interior reduces moisture accumulation).

FAQ

Q: What surface treatments are available, and how do they affect cost and performance?

A: Options include: 1) Black oxide coating (lowest cost, adds 5–7% to price, suitable for indoor dry environments); 2) Phosphating (adds 10–12% to price, improves paint adhesion for outdoor use); 3) Hot-dip galvanization (adds 15–20% to price, provides 10+ years of outdoor rust resistance). We recommend galvanization for outdoor or humid applications (e.g., construction sites, water treatment plants).

Q: Can it be bent or welded on-site, and what equipment is needed?

A: Yes—Grade 1010/1020 steel’s low carbon content ensures excellent weldability (compatible with MIG, TIG, and stick welding) and bendability (minimum bend radius is 3x OD for cold bending, 2x OD for hot bending). Standard equipment (e.g., pipe benders, portable welders) works; no special tools are required.

Q: What is the maximum working pressure, and how does it vary with size and wall thickness?

A: Maximum working pressure depends on wall thickness and grade: For 1-inch OD tubes (Grade 1020, 3.38mm wall), it’s 8 MPa; for 4-inch OD tubes (Grade 1020, 6.02mm wall), it’s 4 MPa. Thicker walls increase pressure capacity—e.g., a 4-inch OD tube with 12.7mm wall can handle up to 7 MPa. We provide a pressure rating chart for custom sizes upon request.