1. Understanding the Importance of Auto Rear Beam Tubes

Auto rear beam tubes are an essential part of a vehicle’s suspension system. They connect the rear axle and suspension system to the vehicle’s chassis, ensuring that the rear wheels are properly supported. The rear beam tube helps distribute weight and provides the necessary strength for the suspension system to perform effectively, especially under load.

In recent years, Reinforced Auto Rear Beam Tubes have become an increasingly popular option in vehicle manufacturing, particularly in performance vehicles, off-road models, and heavy-duty commercial trucks. Compared to standard automotive components, reinforced auto rear beam tubes offer improved strength, safety, and durability. This article compares reinforced auto rear beam tubes with standard components to highlight the key advantages and why choosing reinforced versions can benefit both manufacturers and vehicle owners.

2. What is a Reinforced Auto Rear Beam Tube?

2.1 Material Composition of Reinforced Auto Rear Beam Tubes

A Reinforced Auto Rear Beam Tube is typically made from high-strength steel alloys such as 16Mn or other advanced materials designed for strength and durability. These materials undergo specialized heat treatments and surface coatings to enhance their performance.

The reinforced tube structure allows it to handle higher levels of stress compared to standard tubes. Reinforced tubes are designed with the understanding that modern vehicles, especially those used in off-road conditions or carrying heavy loads, require components that can withstand extreme forces.

2.2 Design Features

The design of reinforced auto rear beam tubes involves several important considerations:

Thicker Walls: The walls of reinforced tubes are thicker, adding to the strength and resistance to deformation.

Improved Torsional Strength: Reinforced tubes can resist torsional forces better, meaning they are less likely to twist or bend under load.

Corrosion Resistance: Coatings like galvanization or powder coating are often applied to prevent rust and ensure longevity.

Optimized Shape: The shape of the tube is optimized for maximum strength, with additional reinforcements at key stress points.

These features make the reinforced auto rear beam tube a more robust and reliable choice for heavy-duty use.

2.3 Primary Benefits of Reinforced Auto Rear Beam Tubes

Improved Safety: Better at absorbing crash forces and protecting occupants.

Enhanced Durability: Longer lifespan and resistance to wear and tear.

Greater Load Capacity: Can support heavier loads without failure.

Corrosion Protection: Resistant to rust and environmental damage.

3. What is a Standard Auto Rear Beam Tube?

3.1 Material Composition and Design

Standard auto rear beam tubes are typically made from lower-grade materials such as carbon steel or basic alloys that do not offer the same level of strength as reinforced tubes. These materials may be adequate for vehicles with lighter usage requirements but are less suited for performance vehicles or vehicles that require enhanced durability.

Standard rear beam tubes generally have thinner walls and less robust design features compared to reinforced tubes. They may also lack advanced coatings or protective layers that prevent corrosion and extend the lifespan of the component.

3.2 Performance Limitations of Standard Auto Rear Beam Tubes

Standard auto rear beam tubes are designed for everyday driving and typical load-bearing conditions. However, they have limitations:

Lower Strength: Standard tubes are not designed to withstand extreme stress and may deform or fail under high loads or during collisions.

Corrosion Susceptibility: These tubes are more prone to rust and corrosion, especially when exposed to harsh environmental conditions.

Reduced Durability: Over time, standard tubes can degrade faster due to wear and environmental factors.

3.3 Common Applications of Standard Auto Rear Beam Tubes

Standard tubes are typically found in vehicles designed for light to medium-duty applications:

While these tubes serve their purpose, their performance may fall short under more demanding conditions, which is where reinforced auto rear beam tubes excel.

4. Key Differences Between Reinforced Auto Rear Beam Tubes and Standard Components

4.1 Strength and Durability

Reinforced Auto Rear Beam Tube

Reinforced tubes are designed with higher strength materials and a thicker wall structure, making them far more durable than standard tubes. These tubes are able to handle higher levels of stress without deformation or failure, which is critical for vehicles that are exposed to challenging driving conditions.

Standard Auto Rear Beam Tube

Standard tubes use lower-grade materials and typically have thinner walls. While they may suffice for regular driving, they lack the robustness needed for high-performance or heavy-duty vehicles. Over time, they are more prone to fatigue, bending, and breakage under stress.

Feature | Reinforced Auto Rear Beam Tube | Standard Auto Rear Beam Tube |

Material | High-strength alloys (e.g., 16Mn) | Carbon steel, basic alloys |

Wall Thickness | Thicker for added strength | Thinner walls |

Torsional Strength | Higher resistance to twisting | Prone to twisting under load |

Durability | Long-lasting and resistant to wear | Shorter lifespan, more prone to damage |

4.2 Safety Performance

Reinforced Auto Rear Beam Tubes are designed to provide superior crashworthiness and impact resistance. When a collision occurs, these tubes absorb and distribute the impact energy across a larger area, which reduces the severity of damage to the vehicle’s structure and protects the occupants. The stronger material and enhanced design prevent the tube from failing under extreme conditions.

Standard Auto Rear Beam Tubes, while functional for lighter use, are less effective at absorbing and distributing crash forces. In high-impact scenarios, they are more likely to deform or fail, compromising vehicle safety.

4.3 Handling and Stability

Reinforced Auto Rear Beam Tube

The increased strength and resistance to torsion in reinforced auto rear beam tubes directly contribute to improved handling, especially under high loads, sharp turns, or off-road conditions. Reinforced tubes keep the rear suspension system stable, reducing flex and enhancing the vehicle’s overall handling and ride quality.

Standard Auto Rear Beam Tube

In vehicles using standard tubes, the suspension system may experience more flex, especially under heavy loads or during sharp cornering. This can lead to instability and poor handling, particularly in off-road or high-speed driving conditions.

4.4 Corrosion Resistance

Reinforced Auto Rear Beam Tubes are often treated with protective coatings such as galvanization or powder coating. These coatings prevent rust and corrosion, making the tubes more suitable for vehicles that operate in harsh environments, such as regions with salt-heavy roads or coastal areas with high humidity.

Standard Auto Rear Beam Tubes, on the other hand, are typically not treated with advanced coatings, making them more susceptible to rust and deterioration when exposed to the elements.

5. Performance in Real-World Driving Conditions

5.1 Everyday Driving

For passenger cars and standard SUVs used for everyday commuting, standard auto rear beam tubes may suffice. However, for enhanced safety, stability, and durability, reinforced auto rear beam tubes provide significant advantages. They ensure that the vehicle can handle bumps, potholes, and uneven roads without compromising ride quality.

5.2 Heavy-Duty Applications

For commercial vehicles, off-road vehicles, or sports cars, reinforced tubes are crucial. These vehicles are often subjected to extreme driving conditions, such as carrying heavy loads, navigating rough terrains, or enduring high-speed performance. Reinforced auto rear beam tubes ensure that the vehicle remains stable, safe, and capable of handling these demands.

5.3 Load-Bearing Capacity

Reinforced tubes are specifically designed to bear heavier loads. Whether in commercial vehicles or off-road situations, these tubes can support the weight of additional cargo without losing structural integrity. Standard tubes, while functional in regular use, may fail when subjected to high levels of weight or stress.

6. Durability and Longevity: A Comparative Analysis

6.1 Wear and Tear

Reinforced auto rear beam tubes have a significantly longer lifespan compared to standard tubes. Their resistance to wear, fatigue, and corrosion makes them ideal for vehicles that endure harsh conditions. These tubes require less frequent replacements, making them more cost-effective over time.

Standard auto rear beam tubes are more likely to degrade quicker, especially in high-stress applications, leading to increased repair and replacement costs.

6.2 Fatigue Resistance

One of the standout features of reinforced auto rear beam tubes is their superior fatigue resistance. These tubes are designed to withstand repeated stress cycles, making them ideal for vehicles used in challenging conditions. In contrast, standard tubes may fail after repeated use or under extreme stress.

Feature | Reinforced Auto Rear Beam Tube | Standard Auto Rear Beam Tube |

Resistance to Wear | High durability, resistant to fatigue | Prone to wear over time |

Corrosion Resistance | Anti-corrosion coatings | Basic protection |

Fatigue Resistance | Superior performance in stress cycles | Lower resistance to repeated stress |

7. Manufacturing and Quality Control

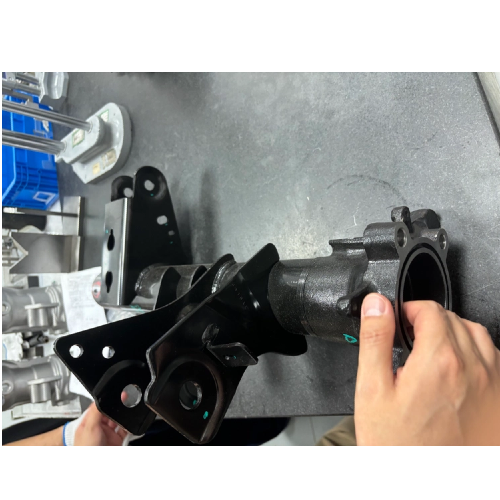

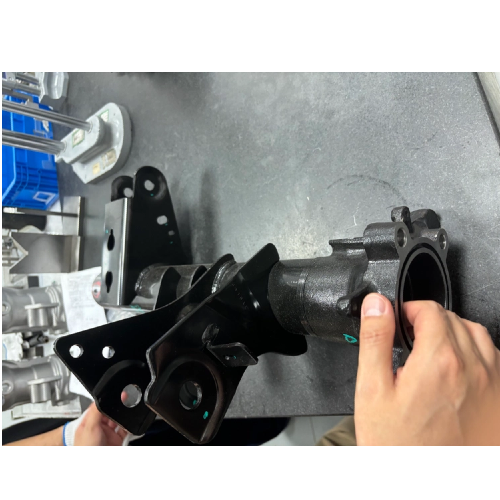

7.1 Production Process of Reinforced Auto Rear Beam Tubes

The manufacturing process for reinforced auto rear beam tubes involves high-precision forming and advanced welding techniques. These tubes are made to stringent quality standards to ensure their strength and durability under demanding conditions.

Hydraulic Forming: This technology shapes the tube precisely without compromising the strength of the material.

Advanced Welding: Reinforced tubes undergo high-quality welding to ensure that the joints are strong and resistant to stress fractures.

Surface Coatings: Protective coatings are applied to ensure corrosion resistance and extended lifespan.

7.2 Standards and Certifications

Reinforced tubes are manufactured in compliance with international standards such as SAE J2632 for rear suspension components and ISO 9001 for quality management systems. These certifications ensure that the tubes meet stringent safety, performance, and durability criteria.

8. Cost Comparison: Reinforced Auto Rear Beam Tubes vs. Standard Tubes

8.1 Initial Cost

Reinforced auto rear beam tubes come with a higher upfront cost due to the superior materials and manufacturing processes involved. However, the enhanced performance and durability they provide justify the investment for many vehicle owners and manufacturers.

Standard auto rear beam tubes are more affordable upfront but may incur higher long-term costs due to more frequent repairs and replacements.

8.2 Long-Term Value

While reinforced tubes cost more initially, they provide significant long-term savings due to their durability and reduced maintenance requirements. For fleet operators and vehicle manufacturers, this makes reinforced tubes a more cost-effective choice in the long run.

9. Conclusion

In conclusion, reinforced auto rear beam tubes provide considerable benefits over standard components, including enhanced safety, durability, performance, and cost-effectiveness. Whether for everyday passenger vehicles, off-road models, or heavy-duty commercial trucks, reinforced tubes offer superior handling, improved crashworthiness, and greater longevity. These tubes are essential for ensuring vehicles can withstand the demands of modern driving conditions. As vehicle requirements continue to evolve, investing in reinforced auto rear beam tubes is a crucial step toward creating more reliable, safer, and durable vehicles.

At Suzhou Baoxin Precision Mechanical Co., Ltd., we specialize in manufacturing high-quality reinforced auto rear beam tubes designed to meet the performance and safety needs of various vehicle types. Our products are engineered for optimal strength, durability, and reliability, providing long-lasting value. If you're looking for reliable, customized rear beam tubes for your vehicles, we invite you to contact us to learn more about our offerings and how we can assist in meeting your specific requirements.

10. FAQ

1. What makes a Reinforced Auto Rear Beam Tube better than a standard tube?

Answer: A Reinforced Auto Rear Beam Tube is made from high-strength materials and features enhanced design features, including thicker walls, better torsional resistance, and superior corrosion protection. This makes it much stronger and more durable than standard tubes.

2. How do Reinforced Auto Rear Beam Tubes improve vehicle safety?

Answer: These tubes improve vehicle safety by better absorbing crash forces and maintaining structural integrity during impacts. They are also more resistant to wear and corrosion, reducing the risk of failure in critical situations.

3. Are Reinforced Auto Rear Beam Tubes necessary for all types of vehicles?

Answer: While reinforced tubes are not necessary for every vehicle, they are highly beneficial for high-performance, off-road, and commercial vehicles that are subjected to heavy loads or challenging driving conditions.

4. How long do Reinforced Auto Rear Beam Tubes last?

Answer: Reinforced tubes have a longer lifespan compared to standard tubes, due to their resistance to wear, fatigue, and corrosion. They can last significantly longer, reducing maintenance and replacement costs over time.

5. Can Reinforced Auto Rear Beam Tubes be customized?

Answer: Yes, reinforced auto rear beam tubes can be customized to fit specific vehicle models, ensuring optimal performance, safety, and durability for different applications.