Finned tubes are vital components in heat transfer systems, used widely in industries like HVAC (Heating, Ventilation, and Air Conditioning), oil and gas, power generation, and more. Their ability to increase surface area for efficient heat exchange makes them indispensable in many industrial applications. However, understanding how finned tubes are manufactured is crucial to ensuring high-quality products that meet specific operational requirements.

In this article, we will explore the detailed manufacturing process of finned tubes, including material selection, manufacturing methods, testing, and quality control. We will also cover the importance of choosing the right finned tube for your application and how to maintain it for optimal performance.

1. What Are Finned Tubes?

Definition of Finned Tubes

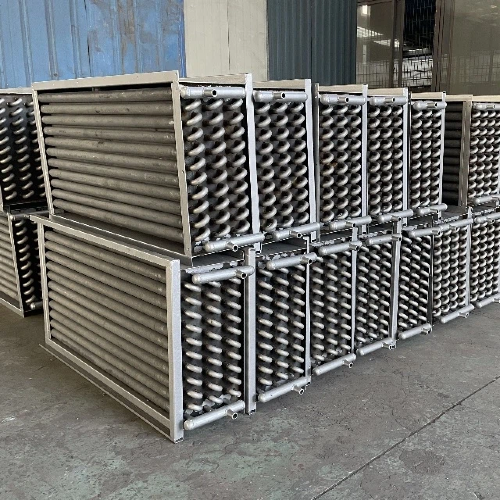

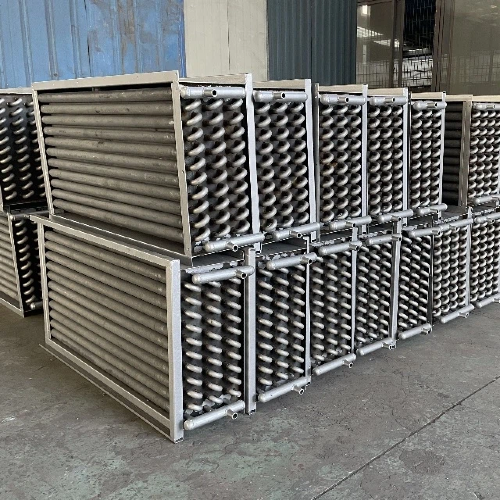

A finned tube is a type of tube that has fins attached to its surface, which significantly increases the surface area for heat transfer. These tubes are primarily used in heat exchangers, boilers, radiators, and other applications where efficient heat exchange between fluids is required. The fins help transfer heat between the inner tube (which carries the fluid) and the surrounding environment.

The purpose of attaching fins to the tube is to enhance the heat transfer capability of the tube without increasing the overall size of the heat exchanger. By increasing the surface area, finned tubes allow for better heat dissipation or absorption, making them essential in many industries.

Components of a Finned Tube

A finned tube consists of two main components:

The Tube: This carries the fluid (liquid or gas) through the system. It is typically made from materials like carbon steel, stainless steel, or copper.

The Fins: These are attached to the outer surface of the tube and are responsible for increasing the surface area for heat exchange. The fins are often made of high-thermal-conductivity materials such as aluminum, copper, or stainless steel.

2. Material Selection for Finned Tubes

Tube Materials

The material used for the tube of the finned tube depends on the application’s requirements, including temperature resistance, corrosion resistance, and mechanical strength. Common materials used for the tube include:

Carbon Steel: Commonly used in applications that do not involve exposure to extreme temperatures or corrosive environments.

Stainless Steel: Used in high-temperature or corrosive environments due to its excellent resistance to rust and corrosion.

Copper: Known for its excellent thermal conductivity, copper is often used in applications that require highly efficient heat transfer.

Finned Material Selection

The fins must also be made from materials that maximize heat transfer while being durable enough to withstand harsh environmental conditions. The following materials are commonly used for fins:

Aluminum: Frequently used due to its good thermal conductivity and lightweight nature. It is also highly corrosion-resistant, making it suitable for use in cooling systems and heat exchangers.

Copper: Chosen for its excellent heat transfer properties, copper fins are used in more specialized applications, particularly where high thermal conductivity is required.

Stainless Steel: Used in high-pressure and high-temperature applications where corrosion resistance is crucial, such as in industrial and chemical processes.

Material Selection Table

To better understand the key material properties for both the tubes and fins, here's a comparison table that highlights the benefits and typical use cases of each material:

Material | Common Use | Advantages | Disadvantages |

Carbon Steel | Standard industrial applications, non-corrosive environments | Cost-effective, strong, durable | Susceptible to corrosion in harsh environments |

Stainless Steel | High-temperature and corrosive environments | Corrosion-resistant, strong, durable | More expensive than carbon steel |

Copper | Heat exchangers, high-efficiency applications | Excellent thermal conductivity, corrosion-resistant | Higher cost, less durable in high-pressure systems |

Aluminum | Air-cooled systems, lightweight applications | Lightweight, excellent corrosion resistance | Lower strength compared to steel, less durable at high pressures |

3. Manufacturing Methods for Finned Tubes

Step 1: Preparing the Tube

Before attaching the fins, the tube is prepared for the manufacturing process. This step involves:

Cutting the Tube: The tube is cut to the desired length based on the specifications for the heat exchanger or other systems.

Surface Cleaning: The tube's surface is cleaned to remove any dirt, rust, or contaminants that could interfere with the bonding or welding process. The cleaning is typically done using abrasive methods or chemical cleaning agents.

After cleaning, the tube is ready to receive the fins, which can be attached using different methods.

Step 2: Attaching the Fins

There are several methods used to attach fins to the tube, depending on the type of finned tube being manufactured and the application it is intended for. The most common methods are:

Welding Method

In the welding method, the fins are welded directly onto the tube. This method is often used in high-pressure applications or where a strong bond between the fins and tube is required. The welding process ensures that the fins are securely attached to the tube, providing a durable and long-lasting bond.

Mechanical Bonding

In mechanical bonding, the fins are mechanically attached to the tube through methods like:

Expanding: The tube is expanded by applying internal pressure, causing the tube to stretch and securely hold the fins.

Coiling: The fins are coiled around the tube and attached by winding them tightly.

Press Fitting: Fins are pressed onto the tube using mechanical force, ensuring they remain in place during operation.

Brazing Method

Brazing involves joining the fins and tube by melting a filler material between them. This method is often used for applications that require a strong, permanent bond without the need for high temperatures. The brazing process is commonly used for making finned tubes for use in high-temperature environments, such as power generation systems.

Spiral vs. Straight Fins

Spiral Finned Tubes: Fins are attached in a helical or spiral fashion, which enhances heat transfer by improving airflow around the tube. This method is commonly used in air-cooled systems.

Straight Finned Tubes: Fins are attached in a linear, parallel fashion along the length of the tube. These are simpler to manufacture and are often used in liquid-cooled systems.

Step 3: Cooling and Finishing

Once the fins are attached, the finned tube must undergo a cooling process to ensure that the bond between the fins and the tube is solidified. After cooling, the fins are often treated or coated to increase durability and prevent corrosion. Common treatments include:

Anodizing: A process used to increase the thickness of the natural oxide layer on the fins, enhancing corrosion resistance.

Painting: Protective coatings are applied to the fins to further protect them from environmental damage.

The finished finned tube is now ready for testing.

4. Testing and Quality Control

Ensuring that finned tubes meet quality standards is crucial to their performance in industrial applications. Several tests and inspections are carried out to guarantee that the product meets the required specifications.

Pressure Testing

Pressure testing is conducted to check the structural integrity of the finned tubes. This test ensures that the tube can handle the expected internal pressures without leaking or deforming. The test is particularly important for finned tubes used in high-pressure applications like boilers and heat exchangers.

Heat Transfer Efficiency Testing

To verify the performance of the finned tubes, heat transfer efficiency is tested. The tubes are subjected to controlled conditions to measure how effectively they transfer heat from the fluid inside the tube to the surrounding environment. This test ensures that the finned tubes will meet the heat transfer requirements of the specific system they are designed for.

Visual Inspection and Measurements

Visual inspection ensures that there are no defects in the fins or tube, such as misalignment, cracks, or irregularities. Measurements are also taken to ensure that the fins are evenly spaced and uniformly attached to the tube. Consistency in fin placement is critical for maintaining optimal heat transfer efficiency.

5. Applications of Finned Tubes

Finned tubes are used in a wide variety of applications where efficient heat transfer is essential. Some of the most common uses include:

1. Heat Exchangers

Finned tubes are widely used in heat exchangers, where they facilitate heat transfer between two fluids. The increased surface area provided by the fins makes these systems highly efficient, especially in air-cooled and liquid-cooled heat exchangers.

2. Boilers and Furnaces

In boilers and furnaces, finned tubes are used to enhance heat transfer from hot gases to water or other fluids circulating in the system. This is particularly important in industrial applications where large amounts of heat need to be exchanged efficiently.

3. Radiators and Cooling Systems

In automotive and industrial applications, finned tubes are used in radiators and cooling systems to dissipate heat from engines, compressors, and other machinery. The increased surface area allows for efficient cooling without increasing the size of the system.

4. Oil & Gas Industry

In the oil and gas industry, finned tubes are used in cooling systems, heat exchangers, and boilers. These systems are critical for processes such as oil refining, petrochemical production, and natural gas processing, where high-temperature fluids need to be cooled or heated efficiently.

6. Benefits of Finned Tubes

There are several key benefits to using finned tubes in industrial heat transfer systems:

1. Increased Heat Transfer Efficiency

The primary benefit of finned tubes is the significant increase in heat transfer efficiency. By adding fins to the tube, the surface area for heat exchange is greatly expanded, which leads to faster and more efficient heat transfer.

2. Compact and Space-Efficient Design

Finned tubes provide a compact design that maximizes heat transfer without requiring large or bulky equipment. This is particularly useful in applications where space is limited but high performance is still required.

3. Enhanced Durability and Performance

Finned tubes are designed to withstand high temperatures, pressures, and corrosive environments. Depending on the materials used, they can have an extended lifespan and provide reliable performance over long periods of use.

4. Cost-Effectiveness

By improving the efficiency of heat transfer, finned tubes can help reduce energy costs over time. They also allow for more compact and cost-effective heat exchanger designs.

7. Maintenance of Finned Tubes

Proper maintenance is essential for ensuring that finned tubes operate efficiently throughout their lifecycle. Regular cleaning, inspection, and monitoring can extend the lifespan of the tubes and help maintain their performance.

1. Cleaning

Regular cleaning is essential to prevent debris or scaling from accumulating on the fins. For air-cooled finned tubes, cleaning can be done using compressed air, brushes, or chemicals to remove dirt and dust. For liquid-cooled systems, it may involve flushing the tubes with water or chemicals to clear blockages.

2. Inspection

Routine inspections should be performed to check for signs of wear, corrosion, or damage to the fins or tube. Any defects found should be addressed immediately to avoid compromising the system’s efficiency.

3. Corrosion Protection

Depending on the operating environment, corrosion can be a significant issue. Using corrosion-resistant materials and applying protective coatings to the fins can extend the lifespan of finned tubes.

8. Conclusion

In summary, finned tubes are a critical component in a variety of heat exchange applications, contributing significantly to improved heat transfer efficiency. Every stage of their manufacturing process, from material selection to the techniques used for fin attachment, plays a vital role in ensuring high performance and long-term durability. Understanding the production of finned tubes and adhering to proper maintenance practices ensures that they consistently provide optimal heat transfer in industrial systems.

At Suzhou Baoxin Precision Mechanical Co., Ltd., we specialize in delivering top-quality finned tubes designed for a wide range of applications. By selecting the right finned tube for your specific needs and following regular maintenance guidelines, industries can enhance energy efficiency, reduce operational costs, and extend the lifespan of their equipment. If you're looking for more information or need assistance in selecting the best solution for your heat transfer needs, we are here to help. Feel free to reach out to us for expert guidance and tailored solutions.

9. FAQ

1. What materials are typically used to make finned tubes?

Common materials for finned tubes include carbon steel, stainless steel, copper, and aluminum. The choice of material depends on the application’s requirements for temperature, pressure, and corrosion resistance.

2. How are fins attached to the tube?

Fins can be attached to the tube using several methods, including welding, mechanical bonding (expanding, coiling, press fitting), and brazing. The method chosen depends on the application’s needs for strength, durability, and efficiency.

3. What is the difference between spiral and straight finned tubes?

In spiral finned tubes, the fins are wound in a spiral pattern around the tube, enhancing heat transfer and airflow. In straight finned tubes, the fins are arranged parallel to the tube, which is simpler to manufacture and effective for liquid-cooled applications.

4. How are finned tubes tested for quality?

Finned tubes undergo pressure testing, heat transfer efficiency testing, and visual inspections to ensure they meet performance standards and are free from defects. These tests ensure the tubes will operate efficiently in real-world applications.

5. What industries use finned tubes?

Finned tubes are used in a variety of industries, including HVAC, boilers, oil and gas, power generation, and automotive applications, for efficient heat transfer in cooling and heating systems.