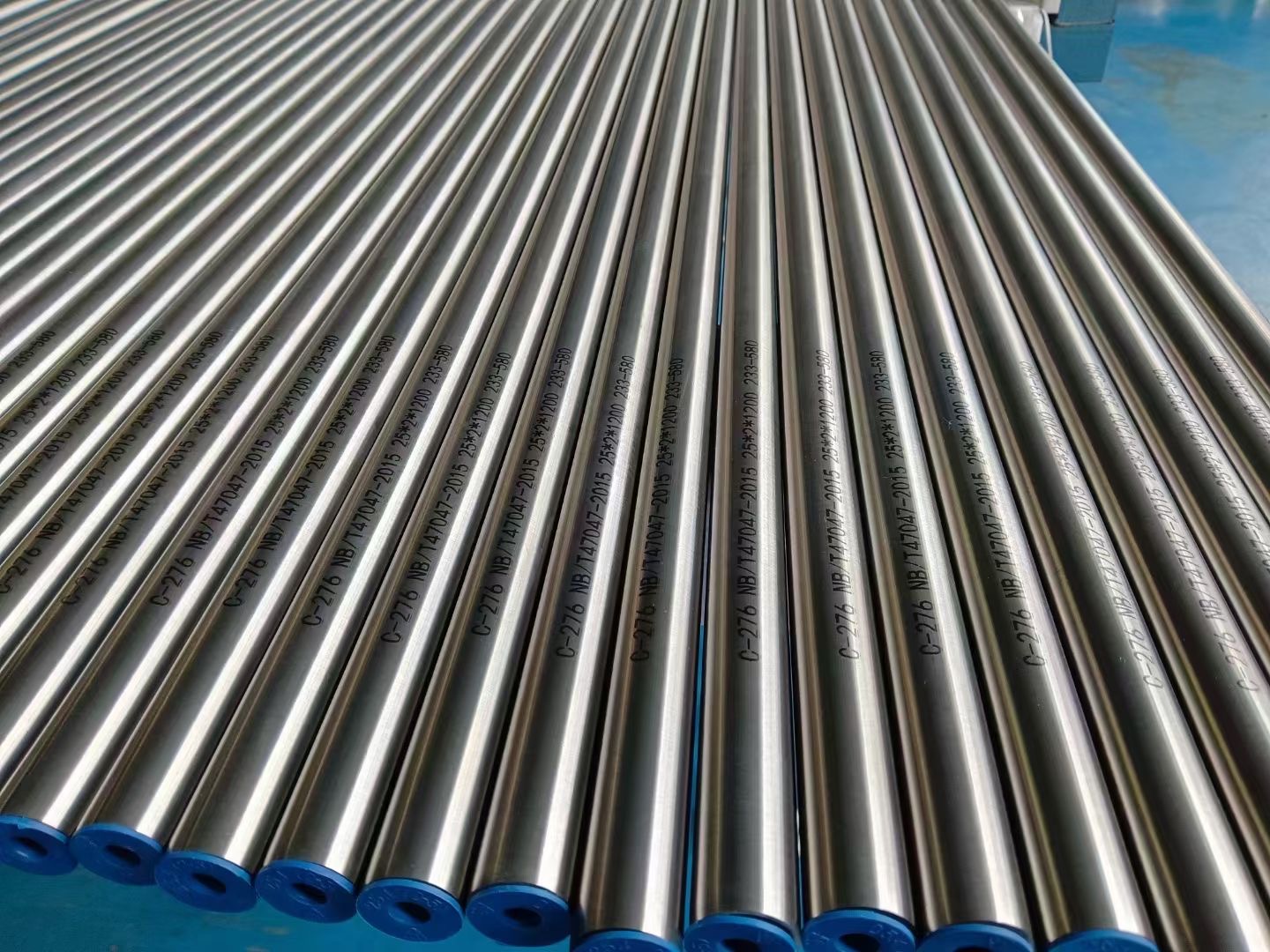

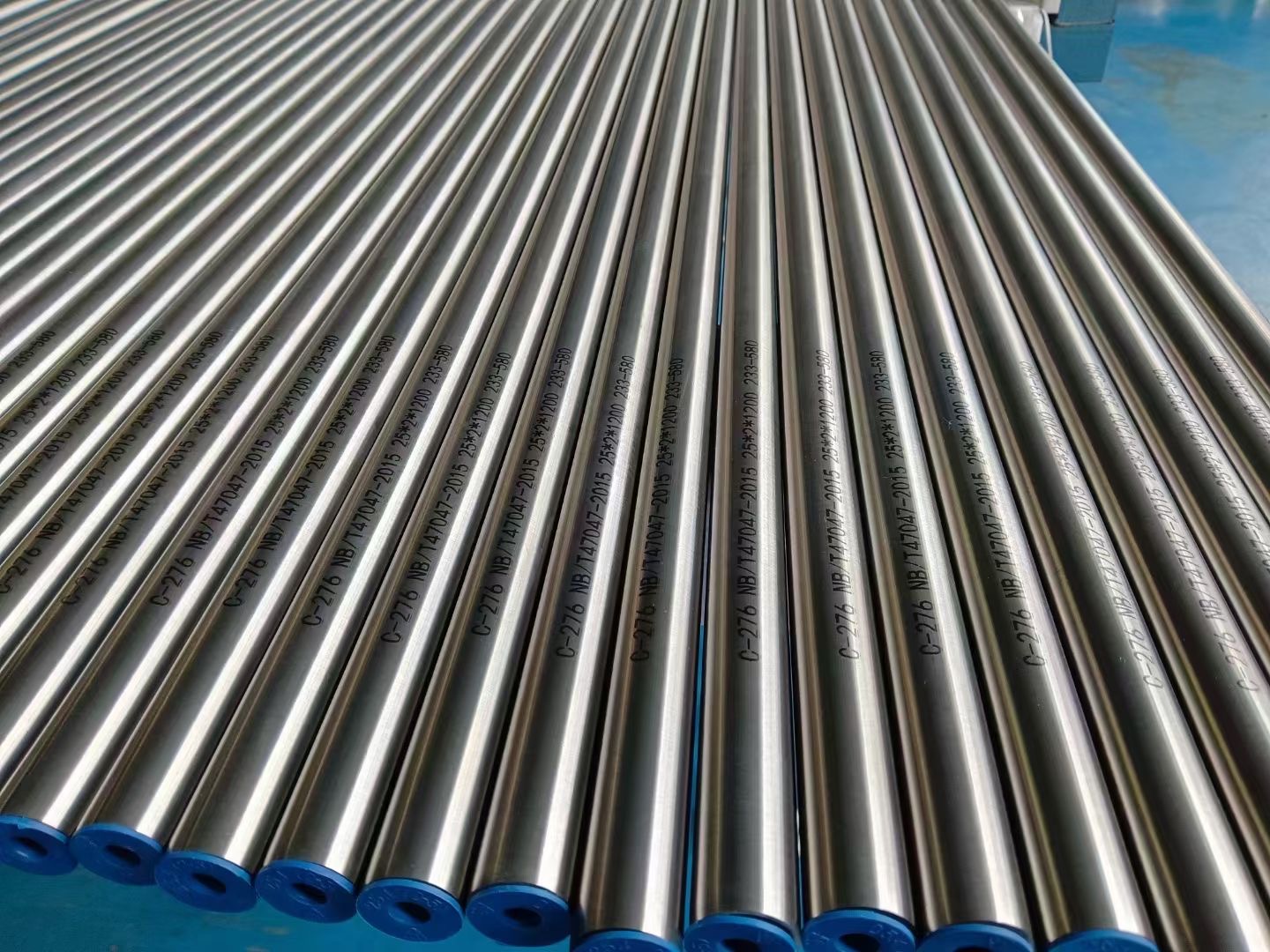

Product Overview

Constructed from 316L stainless steel (2.0-3.0% molybdenum) or 321 stainless steel (titanium-stabilized), it features a seamless design for high-pressure applications. With an outer diameter of 10 inches (254mm) and wall thickness from 3mm to 12mm, it’s optimized for shell-and-tube heat exchangers in refineries, power plants, and chemical facilities.

Product Features

High-Pressure Capacity: Rated for operating pressures up to 3,000 psi (20.7 MPa) at 300℃, with a burst pressure safety factor of 5:1 (ASME B31.1). Seamless construction eliminates weld failure risks in high-stress environments.

Thermal Efficiency: 316L variant offers thermal conductivity of 16.2 W/(m·K) at 25℃, with a polished inner surface (Ra ≤ 0.6μm) reducing fouling by 40% (vs. rough-bore tubes). Extends maintenance intervals by 12-18 months.

Corrosion Resistance: Withstands pH 2-12 (acids like acetic acid, alkalis like sodium carbonate) and sulfur oxide exposure (diesel exhaust). 321 variant resists intergranular corrosion at temperatures up to 800℃.

Dimensional Precision: OD tolerance of ±0.5mm and wall thickness tolerance of ±5% (ultrasonically tested), ensuring compatibility with standard 10-inch flange connections (ANSI B16.5 Class 150).

Applications

Refineries: Crude oil distillation heat exchangers, transferring heat between crude (200℃) and preheated feedstock (80℃) to improve refining efficiency by 5%.

Power Plants: Cooling loops in combined-cycle gas turbines (CCGT), dissipating waste heat to increase power output by 2-3% (critical for grid peak demand).

Chemical Processing: Acid recovery systems (e.g., sulfuric acid concentration), with 316L tubing preventing chemical contamination and ensuring product purity.

Marine Industry: Seawater cooling systems for ship engines, resisting biofouling (barnacles, algae) and saltwater corrosion for 15+ years of service.

FAQ

Q: Why choose 321 over 316L for high temperatures?

A: 321 stainless steel contains 0.10-0.20% titanium, which stabilizes carbon to prevent intergranular corrosion at 600-800℃—ideal for boiler superheaters and exhaust heat exchangers.

Q: What’s the maximum length available?

A: Standard lengths up to 18 meters, with custom lengths up to 30 meters (for large-scale heat exchangers). Cut ends feature ≤0.1mm/m perpendicularity for flange welding.

Q: How is fouling prevented in water-based systems?

A: The polished inner surface (Ra ≤ 0.6μm) reduces calcium carbonate scaling. For hard water (≥200 ppm calcium), we recommend a silica-based anti-fouling coating (adds 200+ hours of scaling resistance).