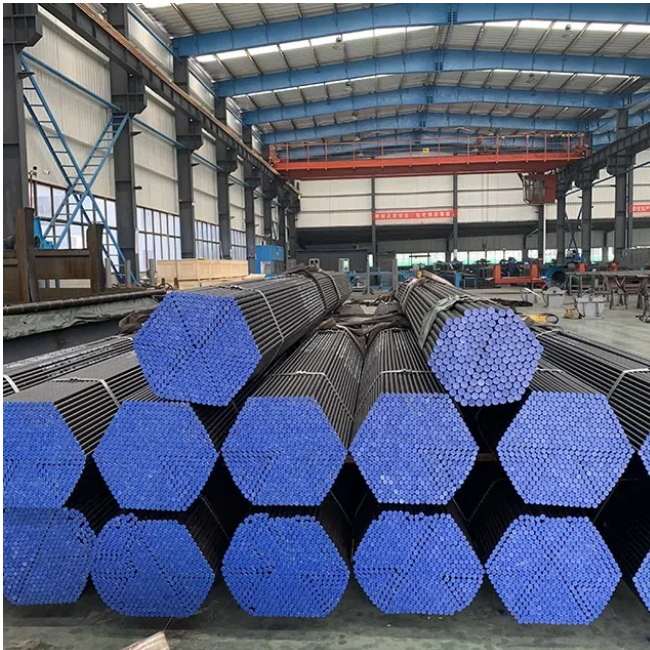

Product Overview

The High-Efficiency Heat Exchanger Tube is a specialized component designed to maximize thermal transfer efficiency in industrial, commercial, and automotive cooling/heating systems—addressing the growing demand for energy-saving HVAC and process equipment. Fabricated to ASTM A213 standards (with additional compliance to ASME BPVC Section I for boiler applications), it integrates advanced material science (e.g., alloy selection tailored to fluid type) with optimized geometry (e.g., micro-finned inner surfaces) to reduce energy consumption by up to 30% compared to standard smooth-bore tubes. Available in three core alloys: copper-nickel (Cu-Ni 90/10 for seawater compatibility), stainless steel (316L for moderate corrosion), and titanium (Grade 2 for extreme corrosives like sulfuric acid)—each matched to specific fluid compatibility needs to avoid premature failure.

Product Features

Enhanced Thermal Conductivity: Achieves thermal conductivity ratings of ≥35 W/(m·K) (316L stainless steel at 25℃) to ≥385 W/(m·K) (copper alloys at 25℃), with micro-finned variants (inner fin height 0.2-0.5mm) further boosting heat transfer by 25% via increased surface area and fluid turbulence.

Low-Friction Interior: Polished inner surface (Ra ≤ 0.8μm, achieved via electrochemical polishing) minimizes pressure drop (reducing pump energy use by 15%) and fouling—specifically reducing calcium carbonate scaling in water-based systems. This extends maintenance intervals by 6-12 months, lowering operational costs for industrial plants.

Pressure Resistance: Rated for operating pressures up to 2,500 psi (17.2 MPa) at 200℃, with a burst pressure safety factor of 4:1 (per ASME B31.3 process piping standards). This ensures safety in high-pressure applications like industrial boilers and refrigeration compressors.

Corrosion Resistant: Titanium variants withstand pH levels from 1 to 14 (resisting acids like hydrochloric acid and alkalis like sodium hydroxide) and are immune to crevice corrosion—making them ideal for chemical processing. Copper-nickel variants, meanwhile, resist marine biofouling (e.g., barnacle growth) in seawater cooling systems.

Applications

HVAC Systems: Condenser and evaporator coils in commercial air conditioning units (e.g., rooftop chillers) for large office buildings, where high efficiency reduces annual energy bills by 5,000-15,000 per unit (depending on size).

Chemical Processing: Heat transfer in acid recovery (e.g., sulfuric acid concentration) and solvent distillation systems (e.g., ethanol purification), with titanium tubes preventing chemical attack and ensuring product purity.

Power Generation: Cooling loops in combined-cycle gas turbines (CCGT) and steam generators, where efficient heat rejection increases power output by 2-3% (critical for utility-scale plants aiming to meet grid demand).

Automotive Cooling: Radiator cores for heavy-duty trucks (e.g., Class 8 semis) and construction equipment (e.g., excavators), with copper alloy tubes delivering fast heat dissipation to protect engines under heavy loads.

FAQ

Q: How much efficiency gain can be expected?

A: Typical systems see 15-40% higher heat transfer rates versus smooth-bore tubes, with variations based on fluid type: water-water heat exchangers (40% gain due to high fluid conductivity), air-water exchangers (15-25% gain due to lower air conductivity), and refrigerant systems (30-35% gain due to enhanced phase change heat transfer).

Q: What is the recommended cleaning frequency?

A: For industrial fluids (e.g., mineral oils, acids), annual chemical cleaning (using pH-neutral detergents for stainless steel, inhibited acids for titanium) is recommended. For potable water systems (e.g., HVAC chilled water), bi-annual flushing (with chlorine-based disinfectants to prevent Legionella growth) suffices.

Q: Can it handle high-velocity fluids?

A: Yes, its robust construction tolerates fluid velocities up to 12 ft/s (3.66 m/s) without erosion—exceeding the 8 ft/s (2.44 m/s) limit of standard tubes. This is critical for high-flow systems like power plant cooling towers, where higher velocity reduces fouling.