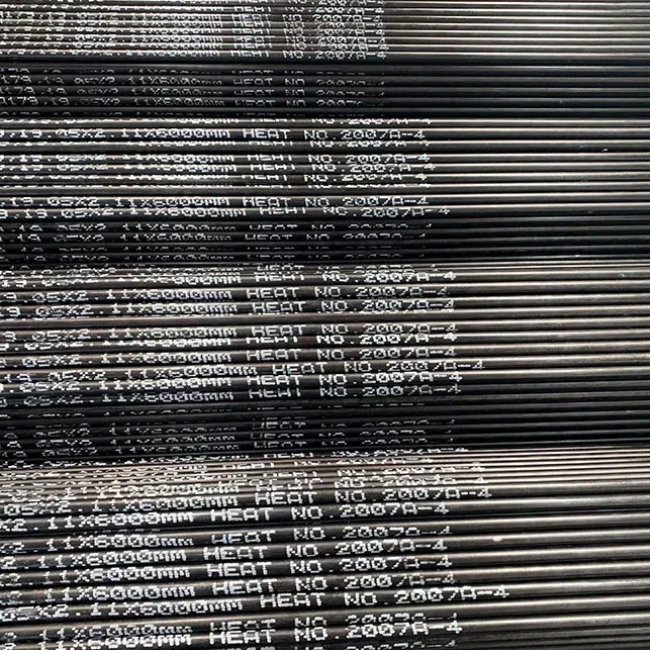

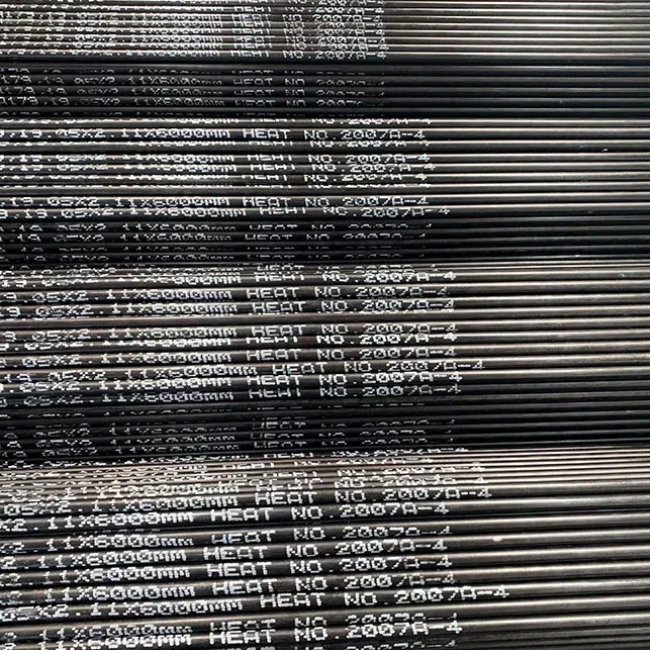

Product Overview

Constructed with ASTM A106 Grade B low-density carbon steel (density: 7.8 g/cm³) via seamless extrusion, it meets API 5L for pipeline transport and ASTM A210 for heat exchange tubes. The low-density alloy reduces installation weight by 10% compared to standard carbon steel, while the seamless design ensures leak-free fluid transfer. It is ideal for automotive manufacturing facilities, industrial plants, and municipal pipeline systems requiring both transport and heat recovery.

Product Features

Lightweight & Strong: The low-density carbon steel (7.8 g/cm³) reduces linear weight to 1.2 kg/m (for 20mm OD, 2mm wall), easing installation and reducing support structure costs. It retains a tensile strength of 415 MPa, meeting pipeline transport requirements for high-flow fluids.

Heat Exchange Performance: Achieves a thermal conductivity of 50 W/m·K, optimizing heat transfer in recovery systems. The smooth inner surface (Ra <0.5μm) minimizes fluid friction, reducing pump energy consumption by 15% compared to rough-wall tubes.

Corrosion Protection: A zinc coating (100μm thickness) provides corrosion resistance in soil and water, with a corrosion rate of <0.05mm/year in pH 6-9 environments. It can be further coated with epoxy for highly corrosive soils (e.g., salt marshes).

Dimensional Versatility: Available in OD from 15mm to 100mm and wall thickness from 1.5mm to 5mm, compatible with standard pipeline fittings (e.g., flanges, couplings) per ANSI B16.5.

Applications

Automotive factory coolant transport lines (transferring and cooling machining fluids).

Industrial process heat recovery systems (capturing waste heat from exhaust fluids).

Municipal hot water distribution pipelines (residential and commercial districts).

Agricultural irrigation systems (transporting water and fertilizer blends).

FAQ

Is it suitable for underground pipeline installation?

Yes, the zinc coating and low-density carbon steel are designed for underground use. Bury at a depth of 0.8-1.2 meters to avoid external damage, and use sand bedding to prevent abrasion. For clay or saline soils, apply an additional epoxy coating (200μm) to extend service life to 20+ years.

Can it handle high-flow fluid transport?

Absolutely. Its smooth inner surface and large ID (e.g., 95mm ID for 100mm OD) support flow rates up to 200 m³/h, meeting the demands of industrial and municipal pipeline systems. The seamless design prevents pressure drops at joints, ensuring consistent flow.

What welding method is recommended?

Use shielded metal arc welding (SMAW) or gas tungsten arc welding (GTAW) for optimal results. Welds should comply with ASME B31.4 (liquid petroleum pipelines) or B31.8 (gas pipelines) depending on the fluid type. Preheat the tube to 100-150°C before welding to prevent cracking.