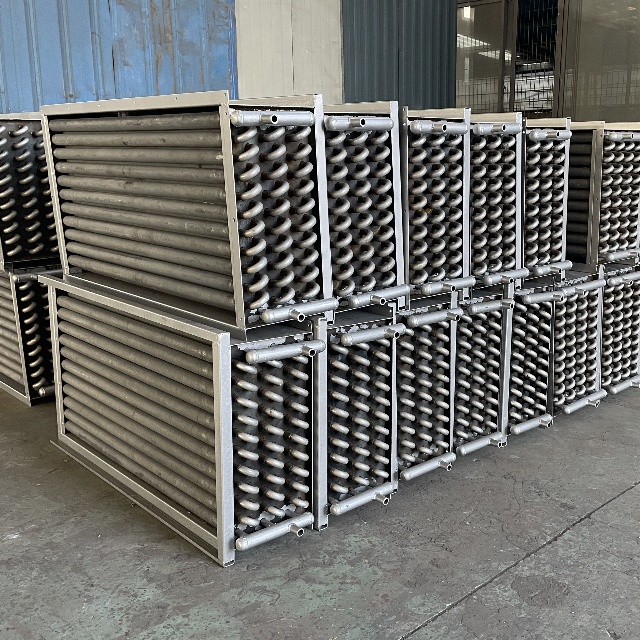

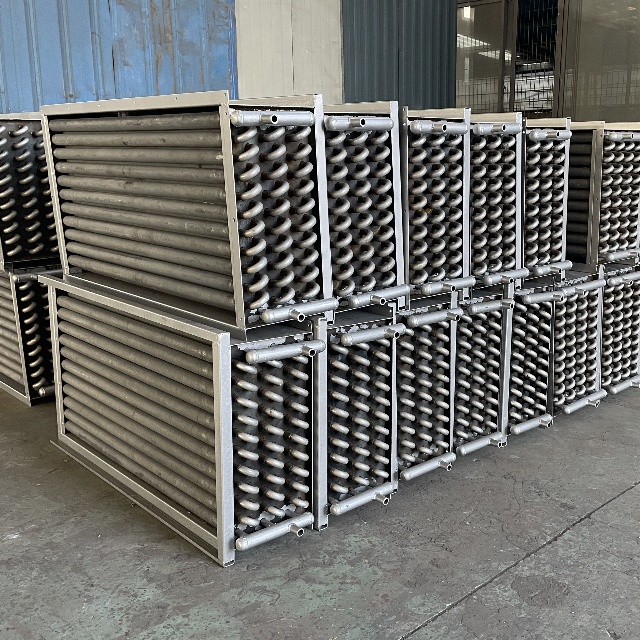

Product Overview

This enhanced heat fin tube redefines thermal exchange efficiency for industrial and commercial systems through a combination of optimized fin geometry, premium material selection, and precision manufacturing. The tube features an integrated fin structure with a triangular design (0.2mm fin thickness, 5mm fin height) that expands the heat transfer surface area by 5-8x compared to smooth tubes—eliminating the thermal resistance of bonded or welded fins. Constructed with 321 stainless steel (06Cr18Ni10Ti), a material chosen for its superior resistance to intergranular corrosion (common in high-temperature applications), the tube is ideal for energy-intensive heating and cooling systems where reliability and efficiency are non-negotiable. Available in customizable fin densities (from 19 to 40 fins per inch), it balances heat transfer performance with fluid flow efficiency, ensuring minimal pressure drop even in high-velocity fluid systems.

Product Features

Heat Transfer Efficiency: The triangular fin design achieves 220 W/m²·K thermal conductivity—a 25% improvement over traditional rectangular fin tubes. This efficiency translates to smaller heat exchanger footprints (reducing installation space by 30%) while maintaining the same thermal output, making it suitable for compact industrial facilities. It also reduces energy consumption by 20-30% in HVAC systems, lowering operational costs for commercial buildings.

Material Durability: 321 stainless steel (06Cr18Ni10Ti) resists oxidation at temperatures up to 800°C, preventing fin or tube degradation in high-heat environments (e.g., industrial boilers). The material also avoids intergranular corrosion when exposed to temperatures between 450°C and 850°C—a common issue with 304 stainless steel that can lead to premature failure.

Corrosion Resistance: Engineered to withstand extreme pH environments (pH 1-14), including acidic solutions (e.g., 20% sulfuric acid) and alkaline solutions (e.g., 50% NaOH). In 50% NaOH solution, it exhibits a corrosion rate of <0.05mm/year—far lower than the 0.2mm/year rate of standard carbon steel fin tubes. This resistance makes it suitable for chemical processing plants where fluids are highly corrosive.

Structural Stability: The fins are bonded to the tube via a hot-rolling process, creating a metallurgical bond with a strength exceeding 15 MPa. This prevents fin detachment under thermal cycling (e.g., repeated heating and cooling in HVAC systems), a common failure point in mechanically attached fin tubes. The bond also ensures uniform heat distribution across the fin surface, eliminating hotspots that can damage the tube.

Applications

Industrial boilers and condensers (e.g., in power plants), where high thermal conductivity and corrosion resistance are essential for steam generation and heat recovery.

Commercial HVAC heating coils (e.g., in shopping malls, office buildings), reducing energy use while maintaining consistent indoor temperatures.

Power generation heat recovery systems (e.g., combined cycle power plants), capturing waste heat from exhaust gases to improve overall plant efficiency.

Petrochemical process heat exchangers, handling corrosive fluids (e.g., crude oil derivatives) and high temperatures up to 600°C.

FAQ

How often should the fins be cleaned?

Cleaning frequency depends on the operating environment: in dusty or airborne particle-rich settings (e.g., manufacturing plants), quarterly cleaning with compressed air (80-100 psi) is recommended to remove debris that blocks fin gaps and reduces heat transfer. In industrial settings with oil or chemical residues, use a 5% citric acid solution (heated to 40-50°C) yearly—avoid harsh detergents, as they can damage the stainless steel surface. For food processing applications, use a food-grade alkaline cleaner (e.g., 2% sodium carbonate solution) to meet hygiene standards.

What fin density options are available?

Standard fin densities range from 19 fins/inch (low density, ideal for high-velocity fluids like steam) to 40 fins/inch (high density, suitable for low-velocity fluids like water). Custom densities (e.g., 12 fins/inch for heavy industrial fluids with high particulate content) are available for specific heat load requirements. When selecting density, consider fluid viscosity: higher viscosity fluids (e.g., oil) require lower fin density to minimize pressure drop.

Can it operate in high-pressure systems?

Yes, when designed per ASME BPVC (Boiler and Pressure Vessel Code) standards, it maintains structural integrity at 10 MPa working pressure (1450 psi). For systems with higher pressures (up to 15 MPa), the tube can be manufactured with an increased wall thickness (from 1.5mm to 3mm) to enhance pressure resistance. It is also tested via hydrostatic pressure testing at 1.5x the design pressure before shipment, ensuring no leaks or structural defects.