Boiler tubes are the backbone of thermal energy systems across industries, from power generation to chemical processing. When functioning optimally, these tubes ensure seamless heat transfer and sustained efficiency. However, one of the most common and costly failures in boiler systems is boiler tube leaks. Understanding what causes boiler tube leaks is not just essential for maintenance engineers, but also for plant operators aiming to reduce downtime and enhance operational longevity.

Understanding Boiler Tubes: Structure and Function

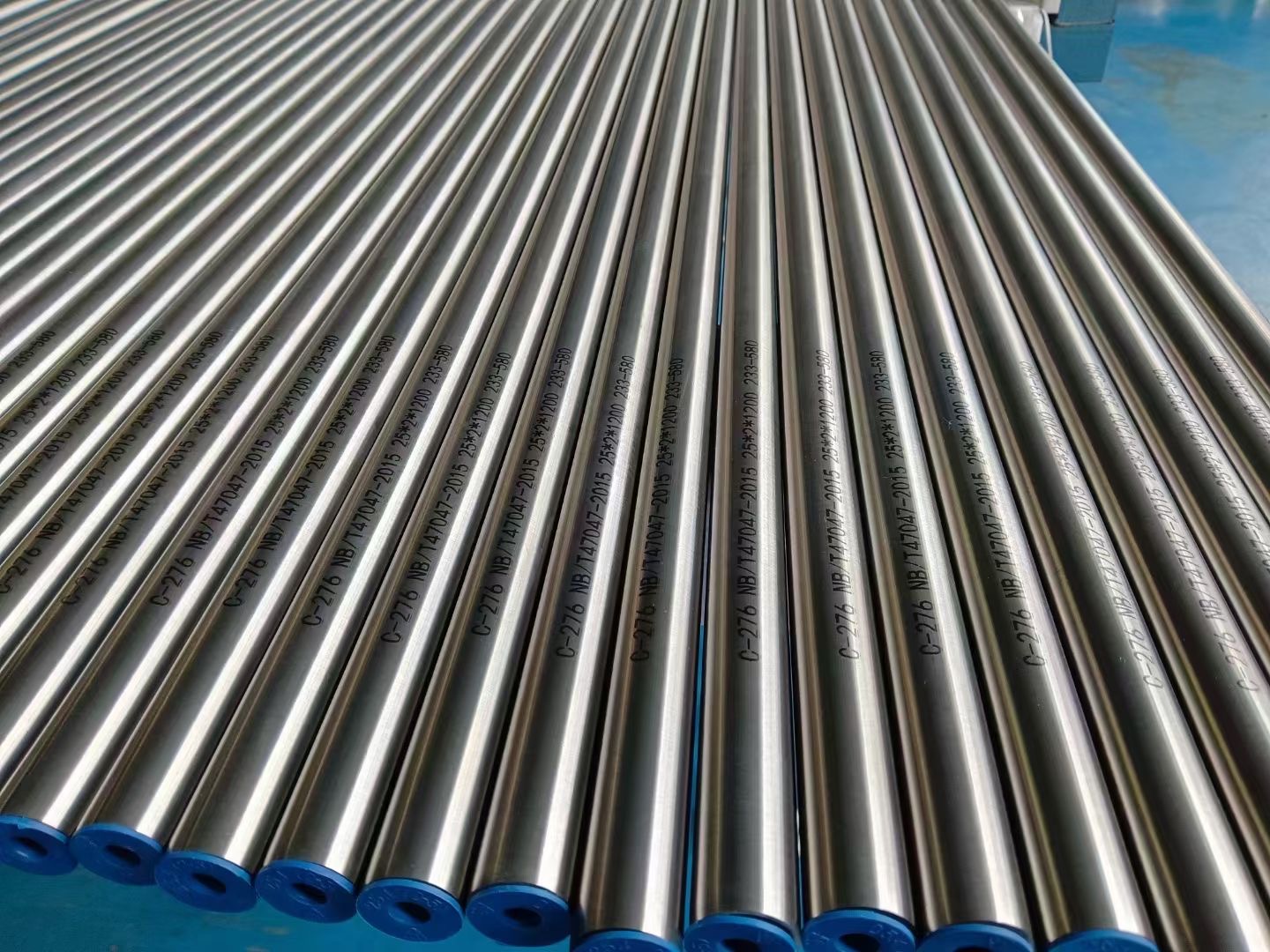

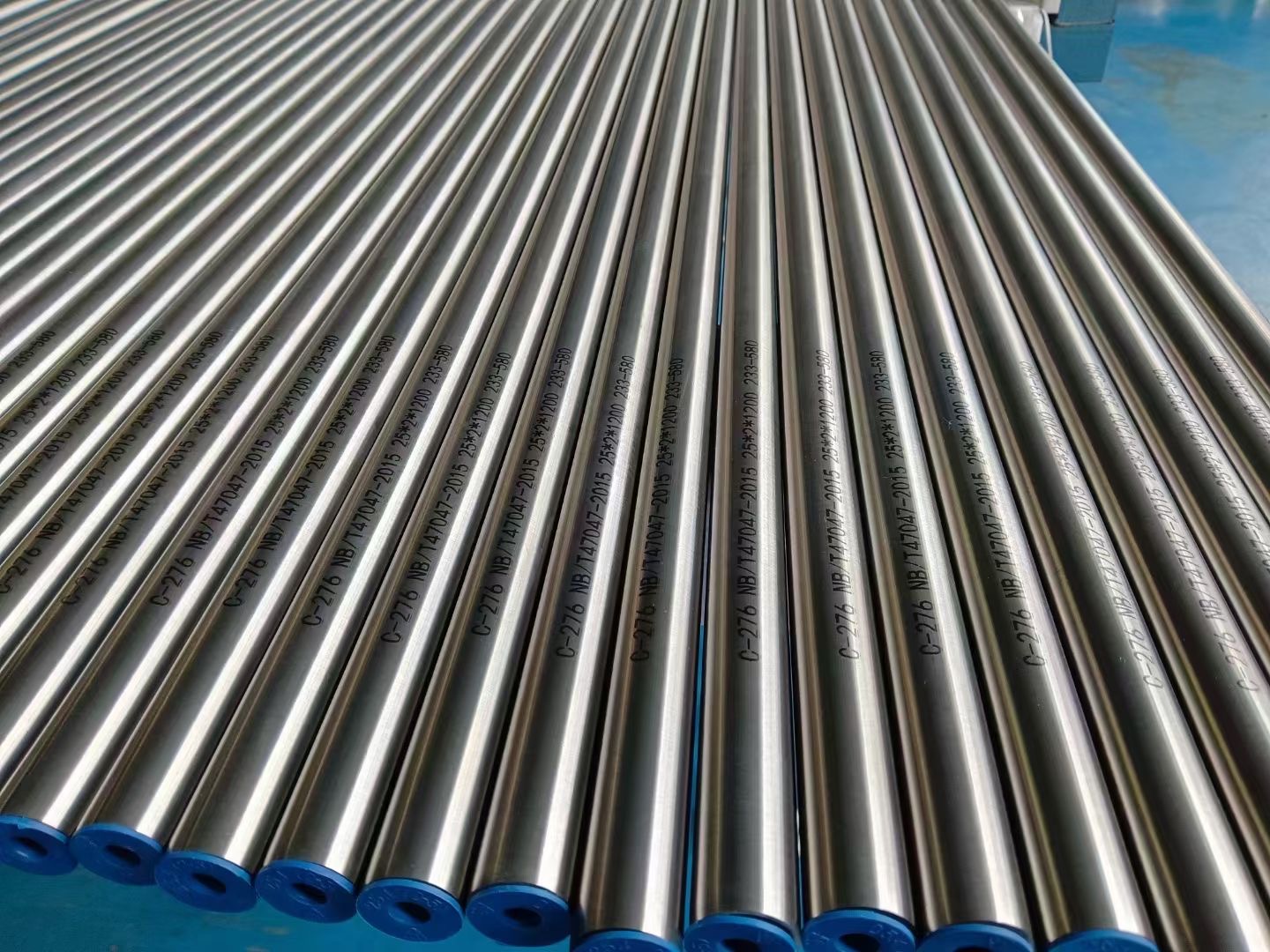

Boiler tubes are high-strength pipes designed to carry high-temperature water or steam under pressure. These tubes are generally categorized into two types: water-tube boilers and fire-tube boilers. In water-tube boilers, water flows inside the tubes while hot gases circulate outside. In contrast, fire-tube boilers have hot gases flowing inside the tubes and water outside.

The failure of these tubes through leaks can lead to catastrophic shutdowns, loss of thermal efficiency, and, in worst-case scenarios, explosions. So, what exactly triggers these leaks?

Primary Causes of Boiler Tube Leaks

The following are the most common causes behind boiler tube leaks. Each of these problems arises due to a complex interaction of operational stressors, material degradation, and environmental factors.

1. Corrosion: The Silent Degrader

Corrosion is perhaps the most prevalent cause of boiler tube failure. It occurs due to the chemical reaction between metal surfaces and oxygen, water, or other corrosive agents. Types of corrosion include:

Oxygen pitting: Localized and severe corrosion caused by dissolved oxygen in feedwater.

Acid attack: Often due to improper pH levels or condensate contamination.

Chelant corrosion: Triggered by overuse or improper mixing of chelating agents in water treatment.

Corrosion gradually thins the tube wall, making it susceptible to rupture under pressure. This process is often slow and undetected until a leak forms.

2. Erosion: High Velocity, High Risk

Erosion typically occurs when high-velocity steam or water, carrying suspended particles, impacts the internal surface of the tube. Over time, this repeated mechanical action wears down the material, creating pinholes or cracks.

Common scenarios include:

Inadequate steam separators

Improperly aligned nozzles

High flow rates with poor condensate return

The most affected areas are typically elbows, bends, or areas with flow disruptions. Erosion corrosion, a combination of both erosion and corrosion, is even more dangerous and aggressive.

3. Overheating and Thermal Fatigue

Boiler tubes operate under extreme temperatures and pressures. When temperature control or water circulation is inadequate, localized overheating can occur. Overheated tubes soften and eventually rupture due to loss of metallurgical strength.

Additionally, thermal fatigue—the cyclic expansion and contraction of tubes—leads to crack formation over time, especially in weld joints and bends. Frequent startup/shutdown cycles worsen this condition.

Boiler designers generally include safeguards, but operational lapses such as scale buildup or flow obstruction can cause hotspots and trigger leaks.

4. Scale Formation and Deposits

Scale forms when dissolved minerals in feedwater, such as calcium and magnesium, precipitate on the internal surfaces of boiler tubes. This acts as an insulating layer, impeding heat transfer.

Consequences include:

Localized overheating

Tube swelling

Thermal stress

Furthermore, scale reduces internal tube diameter, increasing velocity and hence promoting erosion. Maintaining proper water chemistry and regular blowdown schedules is crucial to avoid this.

5. Mechanical Stress and Vibration Damage

Boiler systems are subject to significant mechanical forces—from internal pressure to external vibrations due to adjacent machinery. Improper tube support or wear caused by contact with tube hangers or baffles can result in vibration fatigue or denting.

This type of leak is often insidious because the damage accumulates over time and occurs in less accessible areas of the system. It becomes apparent only when the leak is significant or when an inspection is conducted.

Common Boiler Tube Leak Causes – Summary Table

Here’s a quick breakdown of major causes and their characteristics:

| Cause | Mechanism | Signs/Symptoms | Preventive Measures |

| Corrosion | Electrochemical reaction | Pitting, rust, thinning | Water treatment, deaeration, oxygen scavengers |

| Erosion | High-velocity fluid impact | Localized thinning, flow path damage | Flow control, filtration, baffle integrity |

| Overheating | Poor heat transfer, restricted flow | Bulging, cracking, discoloration | Descaling, monitoring, flow balance |

| Thermal Fatigue | Repeated heating/cooling cycles | Cracks at welds or bends | Smoother startups, stress-relieving materials |

| Scale/Deposits | Precipitation of minerals | Insulation layer, high temperature spots | Water softening, regular blowdown |

| Vibration/Stress | Mechanical resonance or pipe movement | Cracks, metal fatigue near supports | Proper tube support and dampening devices |

How to Detect Boiler Tube Leaks Early

Early detection is critical for minimizing damage. The following methods are widely used in the industry:

Acoustic Monitoring: Leak sounds are distinct and can be detected using ultrasonic microphones.

Thermal Imaging: Hot spots caused by leaks can be identified via infrared cameras.

Pressure Drop Analysis: Sudden pressure dips in the system can indicate tube failure.

Visual Inspection: Scheduled shutdown inspections are still one of the most reliable ways to locate potential issues.

An integrated leak detection system combining these methods often yields the best results.

Frequently Asked Questions (FAQ)

Q1: How long do boiler tubes typically last?

A: With proper maintenance and optimal operating conditions, boiler tubes can last anywhere from 10 to 30 years. However, poor water chemistry or thermal abuse can drastically shorten their lifespan.

Q2: Can boiler tube leaks be repaired, or is replacement mandatory?

A: Minor leaks can sometimes be patched using welding or clamping methods, but replacement is often necessary for structural integrity and safety compliance.

Q3: How often should boiler tubes be inspected?

A: It depends on usage, but typically every 6 to 12 months for high-pressure systems. More frequent checks may be necessary for aging or high-risk equipment.

Q4: Do all leaks cause immediate shutdowns?

A: Not always. Small leaks might go unnoticed initially, but they eventually worsen and can lead to forced outages or unsafe conditions.

Conclusion

Understanding what causes boiler tube leaks is the first step toward preventing costly failures. While corrosion, erosion, overheating, scaling, and mechanical stress are common culprits, the real challenge lies in timely detection and proactive maintenance.

Investing in high-quality water treatment, regular inspections, and staff training can significantly extend the life of your boiler system. Remember, a small leak today can lead to a major shutdown tomorrow. Prevention isn’t just smarter—it’s significantly more economical.