Product Features

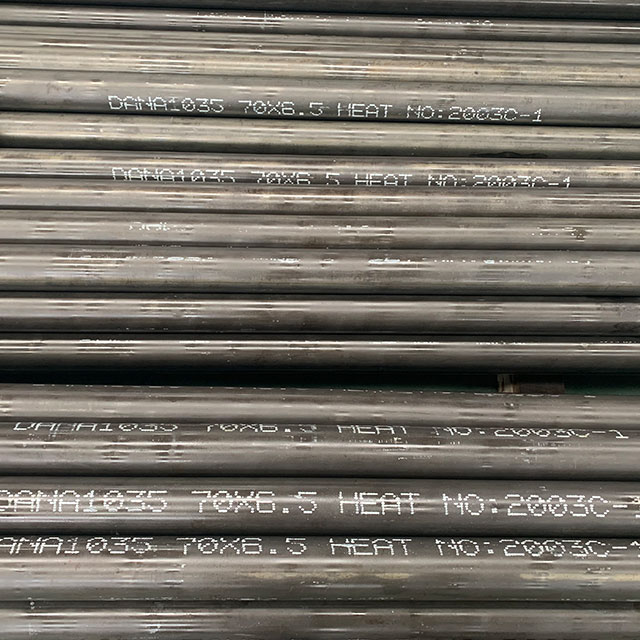

Superior Strength: Made from 4130 alloy steel (heat-treated via quenching + tempering to HRC 28–32), with tensile strength ≥ 760 MPa and yield strength ≥ 655 MPa (per ASTM A519). This material provides 2x the torsional strength of carbon steel sleeves, resisting twisting forces during hard acceleration or towing heavy loads (up to 3 tons).

Load Capacity: Supports maximum axle loads up to 5000 kg (per SAE J2632 testing), ideal for heavy-duty vehicles. The sleeve’s wall thickness (8mm–15mm, customizable) is optimized to balance weight and strength—thicker sections at stress points (e.g., axle flange connection) prevent bending under load.

Corrosion Resistance: Surface treated with black oxide coating (per MIL-DTL-13924) and a clear sealant, resisting rust for 10+ years in humid environments (e.g., coastal regions with salt air). The coating also reduces friction between the sleeve and axle bearings, extending bearing life by 20–25%.

Thermal Stability: Maintains performance at temperatures from -40℃ to 300℃, preventing warping under load—even in high-temperature conditions (e.g., braking hard while towing, which generates heat in the axle). The alloy steel’s thermal conductivity (48 W/(m·K)) dissipates heat quickly, avoiding overheating-related damage.

Applications

Pickup Trucks: Used in full-size pickup trucks (e.g., Ford F-150, Chevrolet Silverado) for towing applications. The sleeve’s high torsional strength prevents axle twist during towing on inclines (10–15% grade), ensuring stable handling.

SUVs: Enhances rear axle strength in 7-seater SUVs (e.g., Ford Expedition, Toyota Sequoia) that carry multiple passengers and cargo. It maintains axle alignment even when the vehicle is fully loaded (800–1000 kg), preventing uneven tire wear and improving braking performance.

Commercial Vans: Supports cargo weight in delivery vehicles (e.g., Mercedes Sprinter, Ford Transit) that transport heavy goods (e.g., appliances, tools). The sleeve’s corrosion resistance is ideal for delivery vans that operate in all weather conditions, reducing maintenance costs.

FAQ

Q: What vehicles is it compatible with, and do you offer custom sizes for rare models?

A: It is available in 20+ standard sizes to fit most domestic (US) and imported trucks/SUVs—compatible with Ford (F-150 2015+, Super Duty), Chevrolet (Silverado 2014+, Tahoe), Toyota (Tundra 2016+, Sequoia), and Mercedes-Benz (Sprinter 2018+). For rare models (e.g., classic trucks, custom builds), we offer custom machining with a 2–3 week lead time—only a sample or detailed dimension drawing is needed.

Q: How is it tested for durability, and what quality certifications do you have?

A: Each sleeve undergoes 100,000-cycle torsional fatigue testing (per SAE J1981) to simulate 200,000 km of use, with no cracks or deformation. It also passes dimensional inspection (via coordinate measuring machine, CMM) and material analysis (via X-ray fluorescence, XRF). We are ISO 9001 certified, and all sleeves meet SAE J2632 automotive axle component standards.

Q: Can it be customized for lifted vehicles, and what is the maximum lift height supported?

A: Yes, extended-length options are available for 2–6 inch suspension lifts—custom lengths range from 150mm to 300mm (standard length is 120mm–180mm). For lifts over 6 inches, we can modify the sleeve’s flange design to fit longer axle shafts, ensuring proper alignment and load distribution.