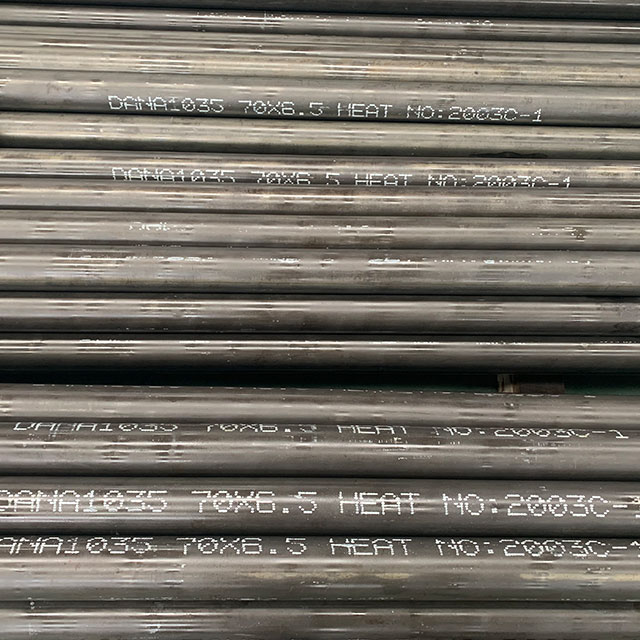

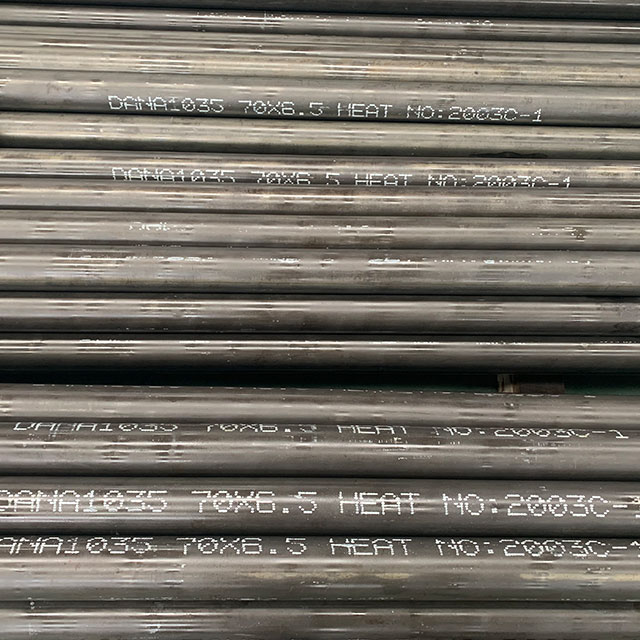

Product Overview

Designed for critical automotive fluid transfer in demanding environments—from daily commuter vehicles to high-performance racing cars—this high-strength auto fuel line tube delivers uncompromising reliability even under extreme engine vibrations and temperature swings. Constructed with premium 4130 alloy steel, which is renowned for its high tensile strength and impact resistance, the tube fully complies with ASTM B210 standards for seamless carbon steel tubes. It strikes a precise balance between flexibility and structural integrity: the material’s malleability allows for easy routing in tight engine bays, while its inherent strength prevents deformation under pressure. The seamless manufacturing process eliminates potential leakage points that are common in welded alternatives, making it a top choice for both OEM manufacturers (such as leading automotive brands) and aftermarket specialists upgrading fuel systems for enhanced performance.

Product Features

Pressure Resistance: Boasts 700 psi working pressure and 2000 psi burst pressure—a 35% improvement over industry averages for gasoline and diesel applications. This high pressure tolerance is critical for high-performance engines (e.g., turbocharged or supercharged models) that demand consistent fuel delivery under extreme load, preventing fuel line collapse or rupture.

Temperature Adaptability: Operates flawlessly in ranges from -58°F to 392°F (equivalent to -50°C to 200°C), maintaining flexibility even at sub-zero temperatures to avoid cracking during cold-start conditions. At high temperatures (e.g., near engine exhaust manifolds), it retains structural stability to prevent fuel vaporization or tube degradation.

Corrosion Protection: Advanced zinc-nickel plating (8-12μm thickness) combined with a clear chromate passivation layer reduces fuel-induced corrosion rate to <0.01mm/year. This protection extends the tube’s service life to 10+ years, even when used with ethanol-blended fuels that are more corrosive than traditional gasoline.

Dimensional Precision: OD tolerance controlled within ±0.02mm, ensuring a tight fit with standard fuel line fittings (e.g., AN 6, AN 8) and eliminating fuel seepage at connection points. The consistent inner diameter also maintains uniform fuel flow, optimizing engine efficiency.

Applications

Automotive fuel delivery systems for passenger cars, compatible with gasoline, diesel, E85 ethanol blends, and B20 biodiesel.

Heavy-duty truck diesel injection lines, where high pressure and durability are essential for long-haul operations.

High-performance racing vehicle fuel circuits (e.g., drag racing, circuit racing), supporting engines with high fuel flow demands.

Agricultural machinery (e.g., tractors, harvesters) fuel transfer systems, resisting corrosion from farm chemicals and outdoor elements.

FAQ

What fuels is this tube compatible with?

It works with gasoline, diesel, ethanol blends up to E85 (85% ethanol, 15% gasoline), and biodiesel blends up to B20 (20% biodiesel, 80% diesel). Avoid direct contact with concentrated acids (e.g., sulfuric acid) or strong solvents (e.g., acetone), as these can damage the surface coating and compromise structural integrity.

Can it be bent during installation?

Yes, the 4130 alloy material allows 90° bends without wall thinning or structural weakening. However, to prevent cracking, the minimum bend radius should exceed 3x the tube’s outer diameter (e.g., a 6mm OD tube requires a minimum bend radius of 18mm). For tighter bends, use a tube bender with a mandrel to maintain inner diameter consistency.

Does it meet safety standards?

Complies with SAE J30R9 (a key standard for high-temperature fuel hoses and tubes) and ASTM B210 (for seamless carbon steel tubes). It also passes 500-hour salt spray tests per ASTM B117, confirming its resistance to rust and corrosion in humid or coastal environments—critical for vehicles used near oceans.