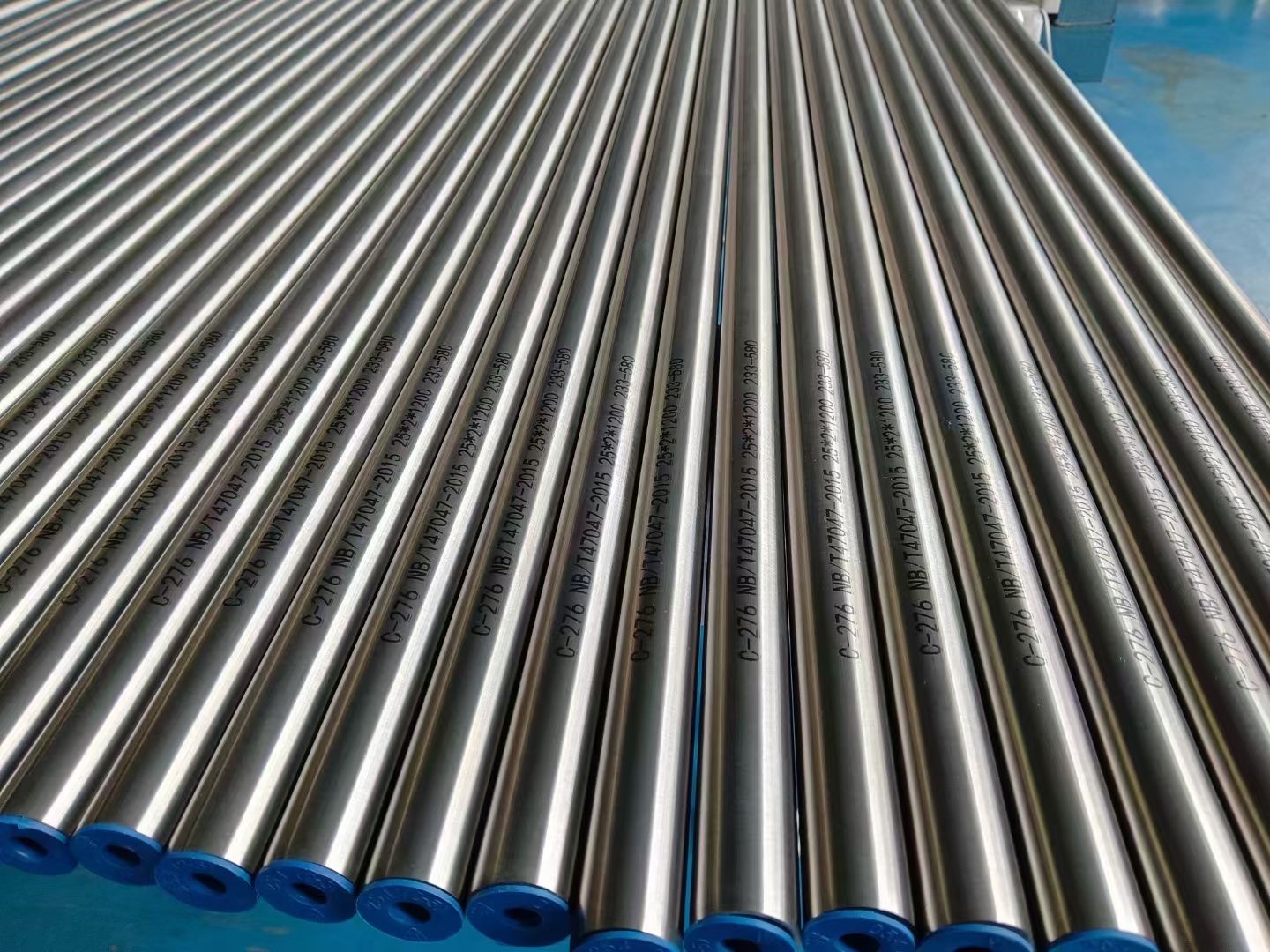

Product Overview

Constructed with 304 stainless steel (18-8 chromium-nickel alloy) via seamless rolling, it meets DIN 17458 for automotive steel tubes and SAE J524 for boiler components. The tube is optimized for automotive boiler sizes (OD ranging from 10mm to 50mm) and features a smooth inner surface to maximize heat exchange efficiency. It is a preferred choice for OEMs manufacturing vehicle parking heaters and auxiliary boiler systems.

Product Features

Heat Transfer Efficiency: The smooth inner surface (Ra <0.2μm) and 304 alloy composition achieve a thermal conductivity of 16.2 W/m·K—25% higher than carbon steel boiler tubes. This reduces boiler warm-up time by 30% (e.g., from 5 to 3.5 minutes for a 5kW heater).

Temperature Tolerance: Operates from -30°C to 450°C, withstanding cyclic heating (engine on/off) without thermal fatigue. It resists oxidation at 450°C, preventing tube blockage from oxide deposits.

Corrosion Resistance: Resists automotive coolant (ethylene glycol-based) and deionized water with a corrosion rate of <0.03mm/year. It passes 500-hour salt spray testing (ASTM B117), making it suitable for vehicles in coastal regions.

Lightweight Design: 304 stainless steel has a density of 7.93 g/cm³, 15% lighter than carbon steel—reducing vehicle weight and improving fuel efficiency. The thin-wall design (1.5mm-3mm) further enhances weight savings.

Applications

Automotive parking heater boiler tubes (providing cabin heat without engine operation).

EV auxiliary boiler systems (heating battery packs in cold climates).

Commercial vehicle (truck, bus) heating coils (supporting large cabin spaces).

Classic car restoration boiler replacements (matching vintage system specifications).

FAQ

Is it compatible with all automotive coolants?

Yes, it works with ethylene glycol, propylene glycol, and hybrid coolants (e.g., HOAT, OAT) used in modern vehicles. Avoid using tap water alone, as mineral deposits can reduce heat transfer efficiency—always mix coolant with deionized water per the manufacturer’s ratio (typically 50:50).

What is the maximum boiler pressure it can handle?

It maintains structural integrity at 10 MPa (1450 psi) working pressure, exceeding the requirements of most automotive boilers (which operate at 2-5 MPa). For high-pressure auxiliary boilers (e.g., 8 MPa), select the 3mm wall thickness option for enhanced strength.

How to maintain optimal heat transfer?

Flush the tube annually with a coolant system cleaner (e.g., citric acid-based) to remove mineral deposits. Inspect for scale buildup (white/grey residue) and descale if needed—scale can reduce heat transfer by up to 40%. Avoid using abrasive cleaners that scratch the inner surface.